Development history

In the late 80s, the Ministry of Automotive Industry announced a tender for the development of an additive to motor oil that would improve the efficiency of internal combustion engines and increase their service life. As a prototype, a product of the Swiss company Lubrifilm, the remetallizer METAL-5, was proposed.

Reference: METAL 5 is a suspension of lead particles in an oil composition. Particle size from 1 micron.

One of the laboratories that took up the study was the laboratory of the Odessa Mechnikov State University. The previous studies of this team were related to the development of conductive elements for the space industry, and some work was carried out with ultra-dispersed fractions of copper. That is why it was decided to test the properties of copper as a remetallizer. The data obtained as a result of the very first experiments were striking in their obviousness: wear was not only significantly reduced, but also the size of worn areas was restored to almost nominal sizes.

But there remained a number of technical and technological problems that needed to be solved. Here are some of them: stabilization of particles in oil, preventing particles from sticking together (with sizes in thousandths of a micron, particles easily form conglomerates), and most importantly, obtaining particles whose real size allows the use of the NANO prefix in industrial quantities, and this involves the development of new equipment and the development of a new technological process, since copper particles of this size turn into oxide in a matter of seconds upon contact with atmospheric oxygen.

Thus, the basis of the development was the method for obtaining an ultra-dispersed fraction of copper. This method made it possible to obtain a powder with particles measuring 0.8 nm — 90 nm. (0.0008 μm — 0.09 μm). A particle of this size contains in its surface layer a number of molecules commensurate with the number of molecules inside the particle, while the activity of the surface layer increases many times, and the particle begins to exhibit properties close to the properties of liquid metal, and this completely changes the very principle of the action of particles on the metal surface. For comparison, the sizes of particles used in other remetallizers are thousands of times larger, and reach 2000 — 3000 nm.

Why was it decided to obtain such a small particle, since the prototype contained a particle of about 1 micron in size?

The fact is that with particle sizes greater than 1 micron, copper can exhibit abrasive properties and the effect would be exactly the opposite. This is one of the reasons why remetallizer manufacturers do not use pure copper, but its alloys using other metals as a plasticizer, and in some cases use other soft metals.

In the case of Remol, the use of pure copper was fundamental, since in the series of electrochemical tension of metals, Copper is to the right of hydrogen, therefore, it is ideally integrated into the iron crystal lattice (you can remember that before plating with chromium, the iron blank is coated with a thin layer of copper). In addition, the copper atom, being integrated into the crystal lattice, displaces the hydrogen atom, thereby reducing hydrogen embrittlement of the metal, which is one of the causes of destruction of the surface of loaded friction pairs. Also, such a small fraction of copper particles begins to exhibit the properties of a catalyst for the fuel combustion process, when even an insignificant amount of particles gets into the combustion chamber.

The shape of Remol-2 particles is spherical, while the particles of other remetallizers in most cases have a scaly shape. Incidentally, I would like to note that smaller particles penetrate the oil filter more freely and do not settle for a longer time after the engine is stopped.

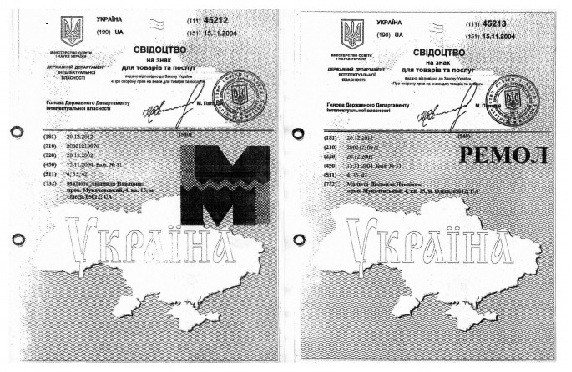

As a result of the work, all technological tasks were successfully solved, and in 1989, first the experimental product Remol-1 appeared, and then, after complex tests, REMOL-2 was released. I would like to note the outstanding contribution to this, as well as the enormous efforts aimed at the implementation of the remetallizant Remol-2 by its developer— Malyuta Lyudmila Pavlovna and Malyuta Nikolai Petrovich — who did a lot to popularize this technology.

During the testing stage, we received significant assistance from AvtoVAZ research staff and engineers: head of the fuel and lubricants laboratory Dorfman V.P., head of the engine refinement department Shishkin Yu.N., head of the engine reliability bureau Byvshev P.Ya. and other research and technical staff.